Dear Visitors We will attend in 2014 CHINA INTERNATIONAL BEARING INDUSTRY EXHIBITION, taking place on 18 Sep, 2014 to 21 Sep, 2014, in SHANGHAI WORLD EXPO EXHIBITION & CONVENTION CENTER. Our Hall Number is: H2, Booth Number is: G128 Thanking you!

Thank you.

Technology

Bearing Material

High carbon chromium bearing steel is the best material for bearing. It features high hardness, strong rolling fatigue resistance, abrasion resistance and stable sizes.

Chemical compositions of GCr15 (SAE52100) are shown on following table.

|

Chemical Composition % |

C

0.95~1.05 |

Cr

1.40~1.65 |

Si

0.15~0.35 |

Mn

0.25~0.45 |

P

|

S

0.02 0.02 |

|

Chemical Composition % |

Ni

0.23 0.23 |

Cu

0.25 0.25 |

Mo

0.1 0.1 |

Sn

0.03 0.03 |

As

0.04 0.04 |

Ti

0.005 0.005 |

|

Chemical Composition % |

Sb

0.002 0.002 |

Pb

0.002 0.002 |

O

0.001 0.001 |

Ai

0.05 0.05 |

Ca

0.01 0.01 |

|

Stainless steel bearing parts material table:

|

Part Name |

INNER RING |

OUTER RING |

BALL |

CAGE |

SHIELD |

SEAL |

|

Material No |

AISI440B

(9Cr18Mo) |

AISI440B

(9Cr18Mo) |

AISI440B

(9Cr18Mo) |

AISI304 |

AISI304(302) |

NBR |

|

AISI440C

(9Cr18) |

AISI440C

(9Cr18) |

AISI440C

(9Cr18) |

AISI304 |

AISI304(302) |

NBR |

The Chemical Composition of different stainless steel number.

|

Stainless steel No |

C% |

Cr% |

Si% |

Mn% |

S% |

P% |

Mo% |

Ni% |

|

AISI440B |

0.90~1.00 |

17~19 |

0.8 0.8 |

0.8 0.8 |

0.3 0.3 |

0.035 0.035 |

|

|

|

AISI440C |

0.95~1.10 |

16~18 |

0.8 0.8 |

0.8 0.8 |

0.3 0.3 |

0.035 0.035 |

0.4~0.7 |

|

|

AISI304 |

0.07 0.07 |

17~19 |

1 1 |

2 2 |

0.3 0.3 |

0.035 0.035 |

|

8~11 |

Tolerance

Bearing tolerance refers to the size accuracy and running accuracy. The different international standard accuracy as below:

|

Standard code |

Precision class | ||||

|

CHINA GB |

0 |

6 |

5 |

4 |

2 |

|

ISO |

0 |

6 |

5 |

4 |

2 |

|

ANSI |

ABEC-1 |

ABEC-3 |

ABEC-5 |

ABEC-7 |

ABEC-9 |

|

SKF |

P0 |

P6 |

P5 |

P4 |

P2 |

|

DIN |

P0 |

P6 |

P5 |

P4 |

P2 |

|

JIS |

0 |

6 |

5 |

4 |

2 |

We offer the bearings with P6, P5 accuracy level.

Bearing Internal Clearance

The internal clearance of running ball bearings greatly influences bearing performance including fatigue life, vibration, noise and heat generation etc. Consequently, it is necessary to select the proper clearance considering the bearing fitting, load, rotation speed and running temperature etc.

Radial internal clearance µm

|

Bore Size (mm) |

C2 |

C0 |

C3 |

C4 |

C5 | ||||||

|

Over |

To |

Min |

Max |

Min |

Max |

Min |

Max |

Min |

Max |

Min |

Max |

|

2.5 |

6 |

0 |

7 |

2 |

13 |

8 |

23 |

- |

- |

- |

- |

|

6 |

10 |

0 |

7 |

2 |

13 |

8 |

23 |

14 |

29 |

20 |

37 |

|

10 |

18 |

0 |

9 |

3 |

18 |

11 |

25 |

18 |

33 |

25 |

45 |

|

18 |

24 |

0 |

10 |

5 |

20 |

13 |

28 |

20 |

36 |

28 |

48 |

|

24 |

30 |

1 |

11 |

5 |

20 |

13 |

23 |

23 |

41 |

30 |

53 |

|

30 |

40 |

1 |

11 |

6 |

20 |

15 |

33 |

28 |

46 |

40 |

64 |

|

40 |

50 |

1 |

11 |

6 |

23 |

18 |

36 |

30 |

51 |

45 |

73 |

|

50 |

65 |

1 |

15 |

8 |

28 |

23 |

43 |

38 |

61 |

55 |

90 |

Noise and Vibration of bearing

The Noise is measured by the instrument of SO910. The Vibration is measured by BVT-1. the data as bellows:

Noise (dB ¡Ü)

|

Bore Size

d (mm) |

Single Bearing Vibration (Acceleration) Limit Value (dB  ) ) | |||||||||||||

|

Diameter Series 0 |

Diameter Series 2 |

Diameter Series 3 | ||||||||||||

|

Z |

Z1 |

Z2 |

Z3 |

Z |

Z1 |

Z2 |

Z3 |

Z4 |

Z |

Z1 |

Z2 |

Z3 |

Z4 | |

|

5 |

37 |

36 |

34 |

30 |

38 |

37 |

34 |

32 |

- |

39 |

37 |

35 |

33 |

- |

|

6 |

37 |

36 |

34 |

30 |

38 |

37 |

34 |

32 |

- |

39 |

37 |

35 |

33 |

- |

|

7 |

39 |

38 |

35 |

31 |

40 |

38 |

36 |

34 |

- |

- |

- |

- |

- |

- |

|

8 |

39 |

38 |

35 |

31 |

40 |

38 |

36 |

34 |

- |

- |

- |

- |

- |

- |

|

9 |

41 |

40 |

36 |

32 |

42 |

40 |

37 |

35 |

- |

- |

- |

- |

- |

- |

|

10 |

43 |

42 |

38 |

33 |

42 |

40 |

39 |

35 |

30 |

46 |

44 |

40 |

37 |

32 |

|

12 |

44 |

43 |

39 |

34 |

45 |

43 |

39 |

35 |

30 |

47 |

45 |

40 |

37 |

32 |

|

15 |

45 |

44 |

40 |

35 |

46 |

44 |

41 |

36 |

31 |

48 |

46 |

42 |

38 |

33 |

|

17 |

46 |

44 |

40 |

35 |

47 |

45 |

41 |

36 |

31 |

49 |

47 |

42 |

38 |

33 |

|

20 |

47 |

45 |

41 |

36 |

48 |

46 |

42 |

38 |

33 |

50 |

48 |

43 |

39 |

34 |

|

25 |

48 |

46 |

42 |

38 |

49 |

47 |

43 |

40 |

36 |

51 |

49 |

44 |

41 |

37 |

|

30 |

49 |

47 |

43 |

39 |

50 |

48 |

44 |

41 |

37 |

52 |

50 |

45 |

42 |

38 |

|

35 |

51 |

49 |

45 |

41 |

52 |

50 |

46 |

43 |

39 |

54 |

52 |

47 |

44 |

40 |

|

40 |

53 |

51 |

46 |

42 |

54 |

52 |

47 |

44 |

40 |

56 |

54 |

49 |

45 |

41 |

|

45 |

55 |

53 |

48 |

45 |

56 |

54 |

49 |

46 |

43 |

58 |

56 |

51 |

47 |

44 |

|

50 |

57 |

54 |

50 |

47 |

58 |

55 |

51 |

48 |

45 |

60 |

57 |

53 |

49 |

46 |

|

55 |

59 |

56 |

52 |

49 |

60 |

57 |

53 |

50 |

- |

62 |

59 |

54 |

51 |

- |

|

60 |

61 |

58 |

54 |

51 |

62 |

59 |

54 |

51 |

- |

64 |

61 |

56 |

53 |

- |

Single Bearing Vibration (Speed) Limit Value (µm/s)

|

Bore Size

d (mm) |

Single Bearing Vibration (Speed) Limit Value (um/s) | ||||||||||||||

|

V |

V1 |

V2 |

V3 |

V4 | |||||||||||

|

L |

M |

H |

L |

M |

H |

L |

M |

H |

L |

M |

H |

L |

M |

H | |

|

5 |

110 |

72 |

60 |

74 |

48 |

40 |

58 |

36 |

30 |

35 |

21 |

18 |

32 |

11 |

11 |

|

6 |

110 |

72 |

60 |

74 |

48 |

40 |

58 |

36 |

30 |

35 |

21 |

18 |

32 |

11 |

11 |

|

7 |

130 |

96 |

80 |

92 |

66 |

54 |

72 |

48 |

40 |

44 |

28 |

24 |

38 |

12 |

12 |

|

8 |

130 |

96 |

80 |

92 |

66 |

54 |

72 |

48 |

40 |

44 |

28 |

24 |

38 |

12 |

12 |

|

9 |

130 |

96 |

80 |

92 |

66 |

54 |

72 |

48 |

40 |

44 |

28 |

24 |

38 |

12 |

12 |

|

10 |

160 |

120 |

100 |

120 |

80 |

70 |

90 |

60 |

50 |

55 |

35 |

30 |

45 |

14 |

15 |

|

12 |

160 |

120 |

100 |

120 |

80 |

70 |

90 |

60 |

50 |

55 |

35 |

30 |

45 |

14 |

15 |

|

15 |

210 |

150 |

120 |

150 |

100 |

85 |

110 |

78 |

60 |

65 |

46 |

35 |

52 |

18 |

18 |

|

17 |

210 |

150 |

120 |

150 |

100 |

85 |

110 |

78 |

60 |

65 |

46 |

35 |

52 |

25 |

25 |

|

20 |

260 |

190 |

150 |

180 |

125 |

100 |

130 |

100 |

75 |

80 |

60 |

45 |

60 |

25 |

25 |

|

25 |

260 |

190 |

150 |

180 |

125 |

100 |

130 |

100 |

75 |

80 |

60 |

45 |

60 |

30 |

32 |

|

30 |

300 |

240 |

190 |

200 |

150 |

130 |

150 |

120 |

100 |

90 |

75 |

60 |

70 |

35 |

40 |

|

35 |

300 |

240 |

190 |

200 |

150 |

130 |

150 |

120 |

100 |

90 |

75 |

60 |

70 |

42 |

45 |

|

40 |

360 |

300 |

260 |

240 |

180 |

160 |

180 |

150 |

130 |

110 |

90 |

80 |

82 |

50 |

50 |

|

45 |

360 |

300 |

260 |

240 |

180 |

160 |

180 |

150 |

130 |

110 |

90 |

80 |

82 |

60 |

60 |

|

50 |

420 |

320 |

320 |

280 |

200 |

200 |

210 |

160 |

160 |

125 |

100 |

100 |

95 |

70 |

70 |

|

55 |

|

|

|

280 |

220 |

200 |

210 |

180 |

180 |

125 |

110 |

110 |

|

|

|

|

60 |

|

|

|

320 |

220 |

240 |

240 |

180 |

200 |

145 |

110 |

130 |

|

|

|

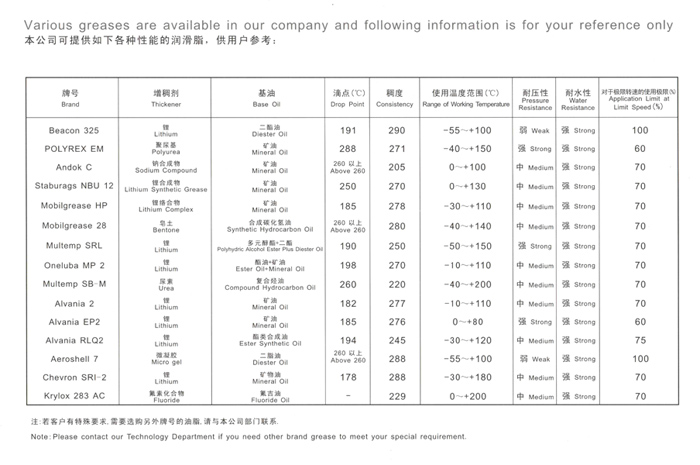

Lubrication

Normally we provide two kind of lubricating method. Oil lubricating and Grease lubricating.

Grease No. of CHBO bearing.

|

Brand |

Grease No. |

Range of temperature |

Characteristic |

|

KYODO |

Multemp SRL |

|

|

|

|

Multemp PS |

|

|